Optical Tables, Breadboards & Workstations

Optical Tables, Breadboards & Workstations

Optical Tables, Breadboards & Workstations

-

TMC CleanBench Laboratory Table

Vibration isolated lab equipment tables for a wide range of applications including scanning probe microscopy, confocal microscopy, interferometry and optical metrology.

- Unique new table-top design (patent pending) combines the best features of TMC's CleanTop steel honeycomb tops with our ultra-stiff, damped, layered platform design.

- Greater stability, especially for small size tables. The low profile, high density tops lower the overall floating center-of-mass ensuring inherently stability, even for relatively top-heavy payloads.

- Guided thread lead-ins to align screws with tapped holes. The "bevel" shape eases engagement of the first thread.

- Ergonomics optimized for the seated user by minimizing the thickness of the table-top. Other designs either offer 100 mm, 4 in. thick tops which awkwardly separate knees and elbows or sacrifice essential mass by offering a 50 mm, 2 in. thick honeycomb top which does not have adequate massfor effective vibration isolation, especially for smaller table sizes.

-

TMC CleanTop Optical Table Performance Series

Industry-leading performance resulting from the highest core density and smallest honeycomb cell area in an all-steel construction. Three performance levels and multiple options available.

- All steel construction – No particle board sidewalls or plastic layer between top skin and honeycomb core. Assures maximum strength and structural integrity.

- Smallest core cell size, highest core density – The CleanTop design does not require enlarging the steel honeycomb core cell size because CleanTop cups are cylindrical, not conical as found in plastic layer designs. CleanTop's average cell size of 0.5 in.(2) is at least 50% smaller than that achieved with plastic layer designs assuring the highest stiffness and greatest core-to-skin bonding contact area.

- Steel to steel to steel – CleanTop achieves a spill-proof core with only two bonding layers: top skin to core and core to bottom skin. Imitations must add a third bonding layer which weakens the structure: top skin to plastic layer, plastic layer to core, and core to bottom skin.

- Thermal stability – The CleanTop all steel construction assures materials of identical coefficient of thermal expansion ensuring optimal thermal stability.

-

TMC Leg and Support Systems

Micro-g Air damped vibration isolation legs to support optical tables - with many configurations of height, weight capacity and vibration isolation performance.

-

TMC CleanTop Optical Breadboards

Exceptionally rigid and well damped steel optical breadboards with 2” or 4” thickness in standard rectangular or customised irregular shapes.

- All steel construction. No particle board sidewalls or plastic layer between top skin and honeycomb core. Assures maximum strength and structural integrity

- Smallest core cell size, highest core density. The CleanTop design does not require enlarging the steel honeycomb core cell size because CleanTop cups are cylindrical, not conical as found in plastic layer designs. CleanTop's average cell size of 0.5 in.(2) is at least 50% smaller than that achieved with plastic layer designs assuring the highest stiffness and greatest core-to-skin bonding contact area

- Steel to steel to steel. CleanTop achieves a spill-proof core with only two bonding layers: top skin to core and core to bottom skin. Imitations must add a third bonding layer which weakens the structure: top skin to plastic layer, plastic layer to core, and core to bottom skin.

- Thermal stability. The CleanTop all steel construction assures materials of identical coefficient of thermal expansion ensuring optimal thermal stability.

-

TMC CleanTop Accessories and Options

A range of options and accessories to configure TMC’s CleanTop optical tables to your exact requirements.

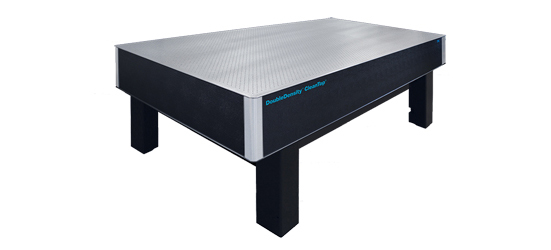

- DoubleDensity™

- Laser Ports

- Alpha-Numeric Grid

- Overhead Shelves

- Laser Shelf

- Rounded Corners

- Earthquake Restraints

- Breadboard Leveler

- Special Materials

- Special Through-Holes and Ports

-

TMC Joined Optical Tables

Rigid coupling plate joiner systems for TMC optical tables to maintain flatness, stiffness and damping.

- Unique process ensures that flatness, stiffness, and damping is maintained across joints.

- Tops may be de-coupled and supported as individual panels.

- Joined Table process is compatible with TMC’s various passive and active vibration isolation support options.

-

TMC LaserTable-Base Active Piezoelectric Vibration Cancellation

Air damping combined in series with STACIS active Piezo damping for the ultimate in high and low frequency vibration cancellation. Ideal for the most critical laser applications.

- Incorporates patented STACIS® technology

- Active inertial vibration cancellation system

- Vibration cancellation starts below 1 Hz

- Extended stroke piezoelectric actuators, up to 60 microns.

- 6 active degrees-of-freedom

- Consists of two isolation systems in series for maximum vibration isolation

- Incorporates patented MaxDamp® Air Isolators

- Simple, robust and cost-effective

- Optional shelves for mounting equipment under the table

- Includes TMC's DC-2020 Digital Controller

-

TMC Non-Magnetic 710 Series

- Smallest core cell size, highest core density. The CleanTop design does not require enlarging the steel honeycomb core cell size because CleanTop cups are cylindrical, not conical as found in plastic layer designs. CleanTop's average cell size of 0.5 in.(2) is at least 50% smaller than that achieved with plastic layer designs assuring the highest stiffness and greatest core-to-skin bonding contact area

- Steel to steel to steel. CleanTop achieves a spill-proof core with only two bonding layers: top skin to core and core to bottom skin. Imitations must add a third bonding layer which weakens the structure: top skin to plastic layer, plastic layer to core, and core to bottom skin.

- Thermal stability. The CleanTop all steel construction assures materials of identical coefficient of thermal expansion ensuring optimal thermal stability.

-

TMC Vacuum Compatible 730 Series

- All steel construction. No particle board sidewalls or plastic layer between top skin and honeycomb core. Assures maximum strength and structural integrity

- Smallest core cell size, highest core density. The CleanTop design does not require enlarging the steel honeycomb core cell size because CleanTop cups are cylindrical, not conical as found in plastic layer designs. CleanTop's average cell size of 0.5 in.(2) is at least 50% smaller than that achieved with plastic layer designs assuring the highest stiffness and greatest core-to-skin bonding contact area

- Steel to steel to steel. CleanTop achieves a spill-proof core with only two bonding layers: top skin to core and core to bottom skin. Imitations must add a third bonding layer which weakens the structure: top skin to plastic layer, plastic layer to core, and core to bottom skin.

- Thermal stability. The CleanTop all steel construction assures materials of identical coefficient of thermal expansion ensuring optimal thermal stability.

-

TMC ClassOne 790 Series for Cleanrooms

- All steel construction. No particle board sidewalls or plastic layer between top skin and honeycomb core. Assures maximum strength and structural integrity

- Smallest core cell size, highest core density. The CleanTop design does not require enlarging the steel honeycomb core cell size because CleanTop cups are cylindrical, not conical as found in plastic layer designs. CleanTop's average cell size of 0.5 in.(2) is at least 50% smaller than that achieved with plastic layer designs assuring the highest stiffness and greatest core-to-skin bonding contact area

- Steel to steel to steel. CleanTop achieves a spill-proof core with only two bonding layers: top skin to core and core to bottom skin. Imitations must add a third bonding layer which weakens the structure: top skin to plastic layer, plastic layer to core, and core to bottom skin.

- Thermal stability. The CleanTop all steel construction assures materials of identical coefficient of thermal expansion ensuring optimal thermal stability.

-

TMC Hybrid Honeycomb Breadboards

Machined from solid aluminium with a bonded underside skin to provide the best combination of surface precision with honeycomb rigidity and damping for customised and OEM requirements.

- Machined, monolithic aluminum panel ensures precision flatness, parallelism, and hole tolerance can be achieved. Comparable tolerance to machined aluminum plates Honeycomb core machined from solid aluminum plate.

- Epoxy bonded face sheet seals honeycomb core and provides additional stiffness and damping Dimensional precision of a machined aluminum plate with the damping and high stiffness-to-mass ratio of a honeycomb breadboard

-

TMC STACIS III Active Vibration Cancellation System

**The market leading STACIS III is being replaced in Q2 2024 by a new and improved STACIS 4, with even higher performance for the most demanding applications**

Designed to filter out floor motion using inertial vibration sensors and piezo actuators with complex control algorithms. Can be used in series with air damped supports to completely cancel environmental vibration at low and high frequencies.

- Hundreds of times stiffer than air isolators – STACIS suffers from none of the limitations of air vibration isolation systems. There is no "soft" suspension and, unlike active air systems, STACIS can be placed beneath a tool with an internal active air isolation system with both systems fully optimized.

- The unique serial design and proprietary high-force piezoelectric technology – results in a wide active bandwidth from 0.6 Hz to 150 Hz and unmatched, truly active vibration isolation with 90% vibration reduction starting at 2 Hz.

-

TMC STACIS 4 Piezoelectric Active Vibration Cancellation

STACIS® 4 is the most advanced active vibration isolation system commercially available. Employing inertial vibration sensors, sophisticated control algorithms, and state-of-the-art piezoelectric actuators, STACIS cancels vibration in real time by continuously measuring floor activity, then expanding and contracting piezoelectric actuators to filter out floor motion. The STACIS 4 builds upon the success of TMC's proven STACIS technology, which is used by 9 of the top 10 semiconductor manufacturers worldwide.