IWATSU Electric Co Ltd, founded in 1938 in Tokyo, offers a wide range of curve tracers and parametric testers for the semiconductor industry. Their advanced equipment features a Source Measure Unit (SMU) capable of delivering up to 5 kV and 2 kA, with support for pulse output, gate pattern control, and microcurrent measurement. These capabilities make IWATSU's solutions especially well-suited for design evaluation of wide-bandgap semiconductors such as SiC (Silicon Carbide) and GaN (Gallium Nitride).

IWATSU Electric Co Ltd

-

IWATSU Semiconductor Curve Tracer CS-3000 Series

Ideal for measuring the characteristics of various semiconductors such as IGBTs, MOSFETs, transistors, and diodes, etc.

- Maximum peak voltage 3,000V (high voltage mode)

- Maximum peak current 1,000A (CS-3300 high current mode)

- All models equipped with LEAKAGE mode (1pA cursor resolution)

- USB port to save screen data and setup data

- Equipped with LAN interface for remote control

-

IWATSU Semiconductor Curve Tracer CS-5000 Series

Ideal for measuring the characteristics of various semiconductors such as IGBTs, MOSFETs, transistors, and diodes, etc.

- Maximum peak voltage 5,000V (high voltage mode)

- Maximum peak current 1,500A (CS-5400 high current mode)

- All models equipped with LEAKAGE mode (1pA cursor resolution)

- USB port to save screen data and setup data

- Equipped with LAN interface for remote control

-

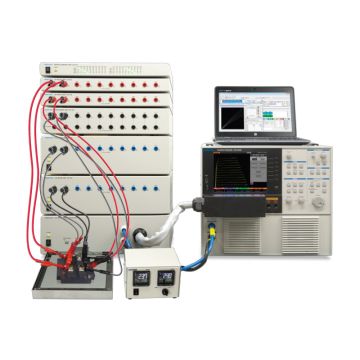

IWATSU Semiconductor Curve Tracer CS-8000 Series

The IWATSU CS-8000 series are equipped with a high-voltage source of up to 5 kV and a high-current source of 2 kA. It features Pulse output, Gate pattern, and very small current measurement capabilities, and it supports the design evaluation of wideband-gap semiconductors such as SiC and GaN.

- Up to 5kV, 2000A High-Power Test

- Accurate very small current Measurement (resolution 250fA)

- Large 12.1-inch Touch Screen

- Variety of GATE Signal Output

- Enhanced Temperature Characteristic Measurement Option

- On-Wafer High-Power Testing with Wafer-Prober

-

IWATSU Semiconductor Parameter Measurement Software CS-810

Automate measurement and improve efficiency. In the past, many items had to be set manually, meaning that measurements took a long time, but by adopting the , it is possible to easily automate measurements, and furthermore, the measurement details can be saved as evidence. In addition, automatic judgment is also possible by setting the threshold value in advance.

Advantages of adoption:

- Make accurate and reliable measurements according to the measurement procedure

- Measurement content is also saved as evidence

- Auto-judgment is also possible

- Control of optional products can also be automated (e.g. temperature control of hot plate)