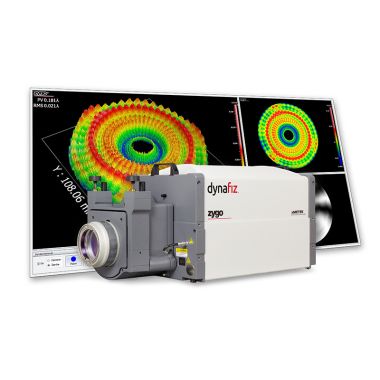

Zygo VeriFire Asphere+ Interferometer

The Verifire Asphere+ (VFA+) builds upon the success of the Verifire Asphere (VFA) Interferometer, which was made specifically for fast, noncontact, high-resolution 3D metrology of aspheric surfaces. The VFA+ uses the latest Zygo MxTM software.

Performance, flexibility, and precise asphere metrology.

Aspheric optics enable significant benefits in the design and implementation of imaging, sensing and laser systems used in industries from defense & aerospace, semiconductor exposure and inspection systems and medical imaging systems.

Production of aspheres that support these applications is dependent on precision metrology. After all, when it comes to aspheric optics, you can’t make what you can’t measure.

The Verifire Asphere+ (VFA+) leverages the benefits of Fizeau interferometry to provide a unique combination of precise, high resolution, fast, and full aperture metrology for axisymmetric aspheres.

The VFA+ provides a flexible metrology platform to measure a range of axisymmetric aspheres with only a change of the transmission sphere. The VFA+ is equipped with an optional secondary stage which supports a computer generated hologram (CGH) extending the asphere shape capability to nonsymmetric freeforms and off-axis aspheric optics.

NEW! With a focus on enhancing the user experience, you can easily set up new measurements, navigate measurement data & results, and diagnose production issues. Mx™ Software enables efficient R&D and prototyping phases and improves production applications with simple one-click setup, alignment and measurement capabilities.

Other features of the VFA+:

- Adaptable to multi-part automated measurement of trays of optics

- Utilise as a standard normal Fizeau interferometer with extreme-precision radius of curvature rail

- Cost effective asphere metrology solution that is future compatible – upgrade existing VFA systems to VFA+!

| SYSTEM | |

| Measurement Capability | Surface form error of axisymmetric asphere optical surfaces with annular stitching, toric surface form error, spherical surface form error and radius of curvature, and freeform, cylinder and offaxis conic metrology with optional CGH stage |

| Measurement Technique | Laser based, three-dimensional, mechanical phase-shifting interferometry combined with heterodyne displacement interferometry |

| Measurement Hardware | Verifire HD-1.2k laser Fizeau interferometer and displacement measuring interferometer |

| Orientation | Downward-looking configuration |

| Test Beam Diam | 6 inch (152 mm) |

| Camera Res | 1200 x 1200 |

| Zoom Range | Discrete zoom turret 1X, 1.7X, 3X |

| Artifact Suppression | Ring of Fire extended source |

| Z-Axis Travel | 820 mm |

| Computer | i7 class PC with 27 in. 1080P display |

| Software | ZYGO Mx software running under Windows 10 (64-bit) |

| ASPHERIC MEASUREMENT PERFORMANCE(1) | |

| Alignment | Automated 5-axis alignment for annular stitching |

| Simple Repeatability(2,3) | ≤1 nm (≤/600) RMS |

| Surface Measurement Repeatability(2,4) | ≤5 nm (λ/1250) RMS |

| Height Resolution | 0.08 nm |

| Cycle Time(5) | 2 - 8 minutes (typical) |

| LASERS | |

| Type | Mainframe: High power stabilized HeNe, Class IIIa DMI: Low power HeNe, Class II |

| Wavelength | Mainframe & DMI: 633 nm |

| Laser Power | Mainframe: >3 mW DMI: <1 mW |

| Frequency Stabilization | Mainframe & DMI: < 0.0001 nm |

| PHYSICAL CHARACTERISTICS | |

| Dimensions (HWD) | 262 x 172 x 150 cm |

| Weight | < 650 kg |

| Utility Requirements | |

| Power | 100 to 240 VAC, 50/60 Hz |

| Compressed Air | 80 psi (5.5 bar); dry and filtered source (for integrated vibration isolation system) |

| OPERATIONAL ENVIRONMENT(6) | |

| Temperature | 15 to 30°C |

| Rate of Change | < 1° C per 15 min |

| Vibration Isolation | Integrated passive isolation Dampens vibration frequencies 1 Hz–120 Hz |

| TEST PART CHARACTERISTICS | |

| Material | Various including glass, metals, ceramics and plastics |

| Aspheric Shape | Annular stitching: Axially symmetric concave and convex with specular surface and measurable vertex |

| Departure from asphere design | Up to 10 µm |

| Departure from best fit sphere |

Approximately 800 µm |

| Part Diameter(7) | 1 mm to 130 mm |

| Part Weight | ≤ 5 kg |

| Reflectivity | 0.1% to 100%(based on transmission element) |

NOTATIONS

- Performance qualified with temperature set point between 20-23°C and temperature stability < 0.5°C.

- Performance dependent on surface slope and departure from design.

- 2δ RMS of 30 measurements using VFA Parabola artifact PN 6024-0484-01.

- Difference of a single measurement from the average of 30 measurements. RMS mean + 2δ.

- Total Average Cycle Time (TACT) estimate for a 3D map with > 1.1 million data points. Includes alignment, acquisition, and analysis, and is dependent on asphere departure.

- These parameters outline the conditions under which the system can operate.

- Range depends on transmission sphere selection

and part specifications.

![]() Zygo VeriFire Asphere+ datasheet

Zygo VeriFire Asphere+ datasheet

![]() Zygo VeriFire Asphere+ specifications

Zygo VeriFire Asphere+ specifications

![]() Zygo Laser Interferometers brochure

Zygo Laser Interferometers brochure

![]() DFNL type CGH with integrated Fizeau Reference Plane Whitepaper, Dr. Florian Hudelist

DFNL type CGH with integrated Fizeau Reference Plane Whitepaper, Dr. Florian Hudelist